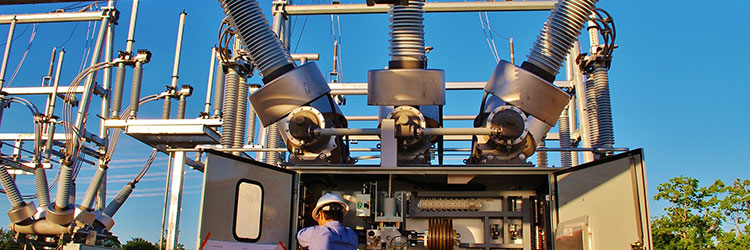

Electrical safety, electrical substation and switchgear maintenance training

Saber Power offers electrical training focused on widely accepted industry standards for safety, electrical power system analysis, maintenance and acceptance testing.

Saber Power’s training courses are for electricians, electrical technicians, HVAC technicians, electrical engineers, electrical safety professionals, electrical field service, electrical engineers and circuit breaker sales professionals, substation managers and substation sales professionals.

The instructors at Saber Power have years of experience in the design, construction, start-up, commissioning, testing, maintenance, and repair of all types of large commercial, heavy industrial and utility electrical power systems and equipment.

As an independent testing company, not affiliated with any equipment manufacturers or suppliers, you can rest assured our electrical training is based on the timeless principles of engineering.

Electrical training courses by Saber Power

Our training department offers private classes and webinars for clients that prefer that option. All classes can be delivered as webinars.

Electrical Safety Courses

Description

Description

Electrical workers must work safely around energized or potentially energized equipment. That is not just an OSHA requirement – it’s common sense. This course teaches electrical workers, from apprentice level and up, the principles of electrical safety needed to plan a job and work it while effectively managing the risks from electric shock and arc flash. Electrical safety concepts are explained in a way which allows workers to understand not only what is required, but how to recognize situations where additional measures may be necessary.

Learning Objectives- Recognize and understand electrical hazards (shock, arc flash and arc blast)

- Apply OSHA’s electrical safe work practices, as well as selected articles of NFPA 70E

- Select, use and maintain personal protective equipment (PPE) used by electrical workers

- Inspect insulated hand tools and insulating protective equipment Perform an absence of voltage test

- Read and understand arc flash labels

- Electricians, electrical technicians, HVAC technicians, supervisors and engineers who work on or are responsible for those who work on energized or potentially energized equipment and circuits.

- Safety professionals who need an understanding of electrical safety.

Course Code: ESQW

Price Per Student: $850 View Available Dates

Description

Description

Managers and supervisors responsible for the people performing electrical tasks are often not qualified electrical workers themselves. It’s not enough to tell workers to be careful. Without an understanding of electrical safety, they could be setting their employees, themselves and their employers up for serious injury, lost time or a fatality and all of the liability that comes with it.

This class enables managers and supervisors to understand and apply what they need to know to ensure their workers are performing electrical tasks safely. Learning Objectives- Recognize and understand electrical hazards and how to plan for them Apply OSHA’s electrical safe work practices, as well as selected articles of NFPA 70E to your safety program

- Perform shock and arc flash risk management

- Ensure that electrical workers are equipped with the proper PPE

- Understand the requirements for testing and inspection of PPE

- Perform field audits

- First-line supervisors, safety professionals who are responsible for employees who work on or with energized or potentially energized equipment and circuits.

Course Code: ESFM

Price Per Student: $575 View Available Dates

Description

Description

All employees must be trained and qualified regardless of their job. Operators in industrial facilities often perform electrical tasks for which they may not be properly trained or qualified. Not only is this a violation of OSHA regulations, but it’s also careless. Untrained workers may not recognize electrical hazards that can lead to personal injury and equipment damage. This class teaches non-electricians the safety principles and practices they need to operate their equipment safely.

Learning Objectives

- Recognize and understand electrical hazards

- Identify situations which may increase the risks associated with operating electrical equipment

- Select, use and maintain required PPE

- Apply safe work practices when operating circuit breakers and disconnecting switches and motor starters

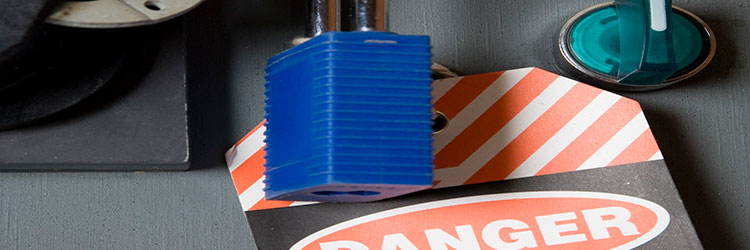

- Understand and apply Lockout/Tagout rules

- Read and understand arc flash warning labels

- Employees who operate electrical devices or equipment but are not trained electricians or electrical technicians. Safety professionals are also encouraged to attend.

Course Code: ESFO

Price Per Student: $575 View Available Dates

Description

Description

Veteran electrical workers aren’t immune from accidents. That is why it’s important for workers to maintain their knowledge and skills throughout their careers. For this reason, both OSHA and the NFPA 70E require periodic refresher training. This course reviews the principles of electrical safety that experienced workers need to plan and work a job while effectively managing the risks from electric shock and arc flash. The training course also covers updates to the 2018 NFPA 70E so that workers stay current on this important industry standard.

Learning Objectives- Identify common accident factors

- Identify electrical hazards and their effects

- Apply OSHA’s electrical safe work practices rules as well as selected articles of NFPA 70E

- Effectively utilize risk management principles to mitigate electrical risks

- Select, use, and maintain electrical PPE

- Read and understand NFPA 70E tables and arc flash labels

- Electricians, electrical technicians, HVAC technicians, supervisors and engineers who work on or are responsible for those who work on energized or potentially energized equipment and circuits. Safety professionals who need to update their understanding of electrical safety should also attend.

Course Code: ESFR

Price Per Student: $575 View Available Dates

Technical Training

Description

Description

Electricians, instrumentation and electronics (I&E) techs, HVAC techs and others who work with electricity must have a basic understanding of how electricity works. Whether you are an apprentice just starting out or an “old hand,” solid knowledge of how electricity works is vital to your success.

This class will help develop new skills and refresh old ones that will help you work more efficiently and safely.

Learning Objectives- Describe the fundamentals of matter and energy

- Use Ohm’s Law to solve simple AC and DC circuit calculations

- Use Ohm’s Law and Kirchoff’s Law in series and parallel circuit calculations

- Understand how electricity is generated

- Apply concepts of inductance, capacitance and reactance

- Electricians, electrical technicians, HVAC technicians, supervisors as well as multi-craft workers who work on, or are responsible for those who work on, energized or potentially energized equipment and circuits.

- Safety professionals who need an understanding of electrical safety.

Description

Description

It has been estimated that more than 70 percent of all electrical problems in industrial, commercial, and institutional power systems are due to poor bonding and grounding of electrical equipment. Without proper grounding and bonding, electrical and electronic equipment is subject to catastrophic damage. Personal injury or death may also result. This electrical grounding and bonding class, based on Soares Grounding and Bonding, 2017, will give participants a comprehensive understanding of practical applications of proper grounding and bonding practices that will help you comply with the requirements of the National Electrical Code.

Learning Objectives- Apply basic fundamental information on electrical circuits, electric shock, and overcurrent device operation

- Perform grounding of electrical systems and equipment for safety

- Identify the fundamentals of grounding for systems, services, feeders, branch circuits, and equipment

- Identify requirements for sizing bonding and grounding conductors and equipment, grounding electrodes and grounding electrode conductors

- Identify requirements for grounding separately derived systems

- Perform grounding at buildings or structures

- Identify requirements for grounding special systems, such as for hazardous (classified) locations, agricultural buildings, health care facilities, swimming pools, and electric signs

- Identify requirements for electronic equipment and limited energy system grounding and bonding requirements

- Understand basic fundamentals on lighting protection

Plant engineers, maintenance managers, electricians, and others who have an interest in grounding and bonding of electrical systems.

Course Duration: 2 Days, 8 a.m.- 4 p.m. Course Code: BOND Price Per Student: $1050 View Available Dates Description

Description

Proper maintenance of electrical equipment is a necessary and vital part of its safe and reliable operation, and it’s tough to do if you don’t know how. Equipment failure and operational issues can be caused by both improper operation and poor maintenance practices.

The result can be costly failures and excessive downtime. Using manufacturers’ literature, NETA, IEEE and NFPA 70B recommended practices, this class provides a better understanding of the testing and maintenance procedures and techniques that will help you maximize the reliability of your electrical system equipment.

Who Should Attend?Electricians, electrical technicians, and others who are involved in or responsible for the operation and maintenance of substation equipment.

Learning Objectives- Perform common electrical maintenance and diagnostic tests

- Describe the principles of electrical testing

- Perform insulation resistance testing with a megohmmeter and a hipot

- Perform low-resistance testing with a DLRO

- Perform a power factor test

- Perform a transformer turns ratio test

Course Code: ETST

Price Per Student: $1050 (live class) View Available Dates

Description

Description

Motors are everywhere. It’s not enough to know that the motor turns when you push a button or throw a switch; it’s necessary to understand what’s happening inside the motor and its control circuit. Knowing how your equipment works is the first step in being able to operate and maintain it properly.

Who Should Attend?Electricians, electrical technicians, mechanical maintenance technicians, supervisors and engineers who operate and maintain or who supervise the operation and maintenance of electric motors in commercial and industrial use.

Learning Objectives- Explain basic motor theory, construction and operation

- Read and understand motor data plate information

- Recognize various motor control systems

- Read motor starting system schematics

- Troubleshoot motor controls

Course Code: MMCC

Price Per Student: $900 (live class)

Price Per Student: $675 (webinar) View Available Dates

Description

Description

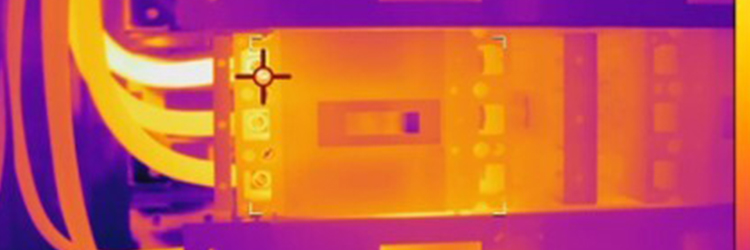

The Level I Certified Infrared Thermographer® course covers the application of qualitative thermal imaging for P/PM, Condition Assessment, Condition Monitoring, Quality Assurance, Forensic Investigations, and Building Sciences.

You will learn infrared theory, heat transfer concepts, equipment operation and selection, standards compliance, image analysis, and report generation.

Course tuition includes all course presentations, Student Reference Manual, and Certified Infrared Thermographer exam. Certification card and diploma issued with passing grade of 80%.

Course is eligible for 35 NETA Continuing Technical Development Credits (CTDs).

Approved by the InterNational Association of Certified Home Inspectors for 32 hours of continuing education; meets the training requirements for their Infrared Certified professional designation and logo.

Approved for 32 Continuing Education Hours (CEH) by the International Institute of Building Enclosure Consultants (IIBEC).

Students supply their own camera, laptop, and software and are encouraged to bring their own imager for individualized training.

Learning Objectives- Know the different types of thermal imagers and components, including detectors, lenses, and display systems.

- Develop skills to capture clear thermal images and interpret the results correctly.

- Understand standards and regulations related to electrical thermography, including personal protective equipment (PPE) and safe working distances.

- Conduct risk assessments to identify potential hazards and implement safety measures.

- Plan and prepare for an inspection, including identifying critical areas and system load conditions.

- Analyze thermal images to identify abnormalities and diagnose potential issues.

- Create comprehensive inspection reports that document findings, analysis, and corrective actions.

- Discover how thermography can be used in a predictive maintenance program to prevent equipment failures

- Electricians, electrical technicians, HVAC technicians, supervisors and engineers who work on or are responsible for those who work on energized or potentially energized equipment and circuits.

- Safety professionals who need an understanding of electrical safety.

Substation and Switchgear Maintenance

Description

Description

No one likes a power system failure, especially when it is caused by poor maintenance. Circuit breakers are a critical component in any power system and ensuring they operate reliably helps you avoid unnecessary down time and expenses resulting from unplanned outages. Poorly maintained circuit breakers can fail to operate properly when needed and the results can be catastrophic to both equipment and employees. This course helps you ensure that your low-voltage breakers are being maintained for maximum reliability and service life.

Learning Objectives

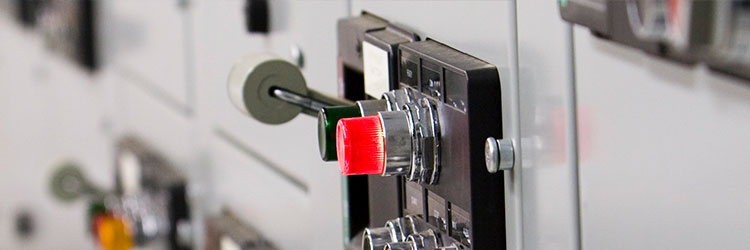

- Describe the construction and operation of low-voltage circuit breakers

- Identify common failure modes

- Perform required visual and mechanical checks and inspections

- Perform common electrical tests such as insulation resistance (Megohmmeter), contact resistance (DLRO), AC and DC over potential (High Pot), timing and primary/secondary injection

- Electricians, electrical technicians, supervisors and others who are responsible for the operation and maintenance of molded case, insulated case and low-voltage power circuit breakers. Field service engineers and salespersons who need a better understanding of circuit breaker testing are encouraged to attend.

Course Code: LVCB

Price Per Student: $875

View Available Dates

Description

Description

No one likes a power system failure, especially when it is caused by poor maintenance. Circuit breakers are a critical component in any power system and ensuring they operate reliably helps you avoid unnecessary down time and expenses resulting from unplanned outages. Poorly maintained circuit breakers can fail to operate properly when needed and the results can be catastrophic to both equipment and employees. This course helps you ensure that your medium-voltage breakers are being maintained for maximum reliability and service life.

Learning Objectives- Describe the construction and operation of medium-voltage circuit breakers

- Identify common failure modes

- Perform required visual and mechanical checks and inspections

- Perform common electrical tests such as insulation resistance (Megohmmeter), contact resistance (DLRO), AC and DC over potential (High Pot), vacuum interrupter integrity and timing

- Electricians, electrical technicians, supervisors and others who are responsible for the operation and maintenance of medium-voltage air and vacuum circuit breakers. Field service engineers and salespersons who need a better understanding of circuit breaker testing are encouraged to attend.

Course Code: MVCB

Price Per Student: $875 View Available Dates

Description

Description

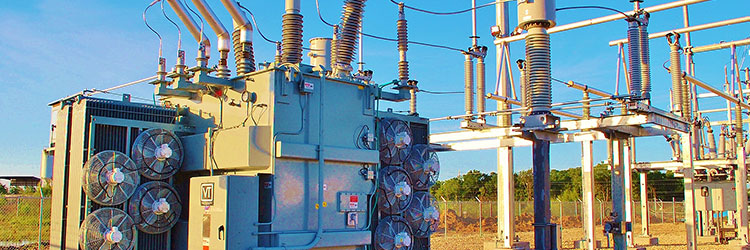

Proper maintenance is a requirement in both utility- and privately-owned substations and it is tough to do if you don’t know how. Mis-operation and equipment failure can be caused by both improper operation and poor maintenance practices; the result can be costly failures and excessive downtime. The operation and maintenance practices that will help you maximize the reliability of your substation equipment are drawn from manufacturer’s literature, NETA, IEEE and NFPA-70B recommendations.

Learning Objectives- Describe the construction and operation of various types of indoor and outdoor substation equipment

- Read and interpret data plate information

- Read and interpret one-line diagrams

- Perform visual and mechanical checks and inspections

- Perform electrical tests commonly used in substations

- Inspect and test ground systems

- Electricians, electrical technicians, supervisors, engineers and managers who operate, maintain or are responsible for the operation and maintenance of medium- and high-voltage substation equipment. Field sales professionals who desire a better understanding of these topics are encouraged to attend.

Course Code: SOMT

Price Per Student: $1200 View Available Dates

Description

Description

Our electrical systems operate at many different voltages, and transformers are the key. They allow us to step voltage up or down as needed to ensure that our equipment has the voltage it needs to operate efficiently. When a transformer fails, that part of the system goes down with it. You can help keep these important (and often expensive) items working at peak efficiency and maximum reliability if you maintain them properly.

Learning Objectives- Explain transformer construction and operation

- Read and interpret nameplate data

- Perform visual and mechanical checks and inspections on transformers

- Identify common transformer oil tests

- Perform electrical tests such as insulation resistance, winding resistance, turns ratio, excitation and power factor tests on transformers and bushings

- Interpret test results using NETA and IEEE guidelines

- Electricians, electrical technicians, supervisors, managers and engineers who work on or are responsible for maintaining transformers in electric power generating stations, substations and commercial distribution systems.

Course Code: XFMR

Price Per Student: $875

View Available Dates

Custom Electrical Training Courses By Saber Power

If you don’t see what you’re looking for, let us know. We can create custom training tailored to your needs.

Saber Training Center

Saber Power, LLC

9841 Saber Power Ln.

Rosharon, TX 77583

8:00 a.m.- 4:00 p.m.

Safety glasses, closed-toed shoes and long pants required for shop and lab tours.